Safety Tips for Using Lifts and Hoists

Share

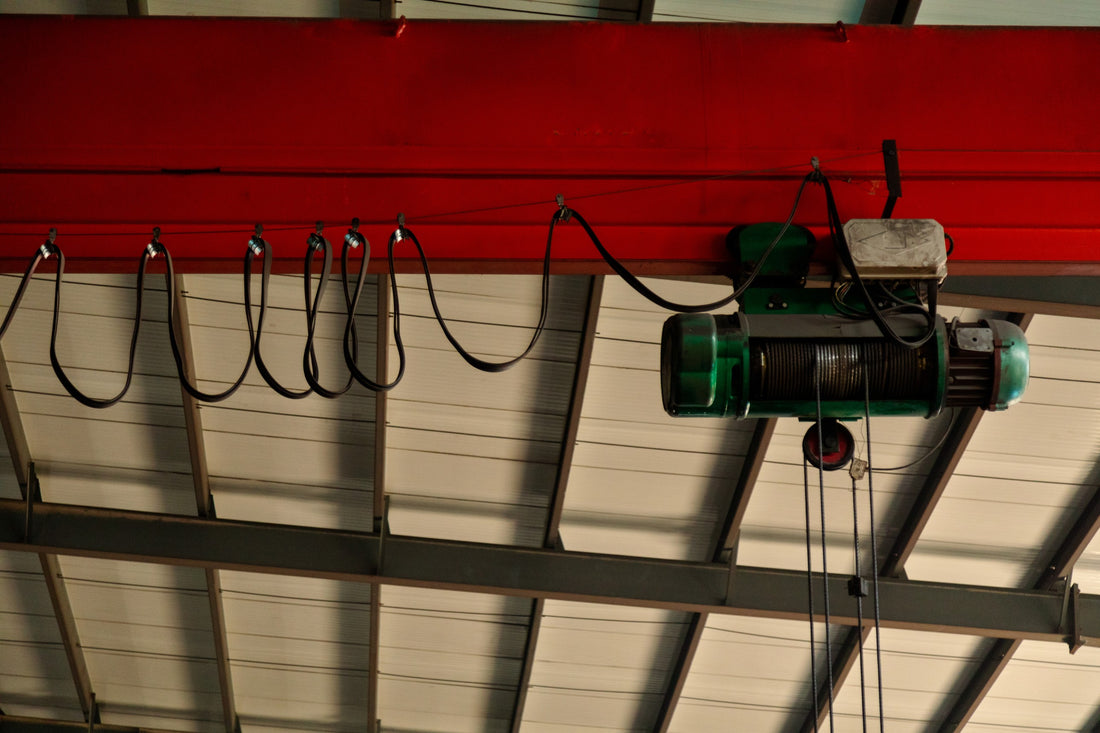

Safety Tips for Using Lifts and Hoists in Industrial Settings

Introduction Lifts and hoists are indispensable tools in many industrial settings, but they also pose significant risks if not used properly. This blog post provides best practices for safely operating these devices, common hazards, safety protocols, routine inspection checklists, and operator training recommendations.

Common Hazards Understanding common hazards associated with lifts and hoists is the first step toward preventing accidents.

-

Overloading: Lifting loads beyond the rated capacity can lead to equipment failure and accidents. Always adhere to the manufacturer's specified load limits.

-

Improper Rigging: Incorrect attachment of loads can cause them to slip or fall, leading to injuries or damage to goods. Ensure proper rigging techniques are used and regularly inspected.

-

Mechanical Failures: Lack of regular maintenance can result in mechanical failures, increasing the risk of accidents. Regular inspections and maintenance are crucial.

Safety Protocols Implementing strict safety protocols can mitigate risks associated with lifts and hoists.

-

Pre-Use Inspections: Conduct visual inspections for any visible damage or wear before each use. This includes checking hooks, chains, and other components.

-

Load Testing: Periodically test the lift or hoist under load to ensure it functions correctly and can handle the specified weight.

-

Operational Guidelines: Always follow the manufacturer’s operational instructions and safety guidelines. Ensure all operators are familiar with these protocols.

Routine Inspection Checklists Routine inspections are critical for maintaining the safety and functionality of lifts and hoists.

-

Daily Inspections: Perform a visual check of hooks, chains, and other components for wear and damage. Ensure all safety devices are in place and functioning.

-

Monthly Inspections: Conduct a detailed inspection of electrical components, brakes, and load limiters. Document any findings and address issues promptly.

-

Annual Inspections: Have a qualified technician perform a comprehensive evaluation of the lift or hoist. This includes load testing and a thorough inspection of all components.

Training and Certification Proper training and certification are essential for ensuring safe operation.

-

Operator Training: Ensure all operators are trained in the proper use of lifts and hoists, including load rigging and emergency procedures. Training should be continuous and updated regularly.

-

Certification: Maintain up-to-date certifications for all operators and ensure compliance with OSHA standards. Regularly review and renew certifications as required.

Conclusion Implementing rigorous safety protocols and regular inspections, combined with proper training and certification of operators, can significantly reduce the risks associated with using lifts and hoists in industrial settings. Prioritizing safety ensures a productive and accident-free workplace.